| 199期:澳门天天好彩AA级公开; 还等啥大胆砸 |

|---|

| 199期:精选九肖:牛猪蛇羊虎鸡猴狗鼠 |

| 199期:精选六肖:牛猪蛇羊虎鸡 |

| 199期:精选四肖:牛猪蛇羊 |

| 199期:精选三肖:牛猪蛇 |

| 199期:精选二肖:牛猪 |

| 199期:精选一肖:牛 |

| 199期:精选尾数:2.7.9.4.8 |

| 199期:家禽野兽:家禽 |

| 199期:平特一肖:单数 |

| 199期:精选十码:29.41.19.37.35.28.09.34.08.18 |

| 199期:精选五码:29.41.19.37.35 |

| 199期:精选三码:29.41.19 |

| 六合活动进行中:站长担保 点击投注 |

| 199期:精选一码:重拳出击-29-信心十足 |

| 198期:澳门天天好彩AA级公开; 还等啥大胆砸 |

|---|

| 198期:精选九肖:羊狗兔龙虎鼠马猪鸡 |

| 198期:家禽野兽:家禽 |

| 198期:平特一肖:单数 |

| 六合活动进行中:站长担保 点击投注 |

| 197期:澳门天天好彩AA级公开; 还等啥大胆砸 |

|---|

| 197期:精选九肖:兔蛇牛鼠虎鸡羊猴狗 |

| 197期:精选尾数:6.0.4.1.3 |

| 197期:家禽野兽:野兽 |

| 197期:精选十码:27.39.37.29.18.28.09.23.34.08 |

| 六合活动进行中:站长担保 点击投注 |

- 澳门四不像精解

- 香港四不像精解

199期今期蛇牛兔出特,二六少妇赶加家开?00准

①杀猴鼠羊(10.22.34.46.06.18.30.42.11.23.35.47)

②图解特肖蛇牛兔虎马

③合双+大数

更多资料尽在18590.com

198期今期龙猪虎出特,一三四七志气高开猪43准

①杀鸡马鼠(09.21.33.45.12.24.36.48.06.18.30.42)

②图解特肖龙猪虎牛兔

③合单+大数

更多资料尽在18590.com

196期今期羊马龙出特,四面春风一路来开龙14准

①杀猪兔牛(07.19.31.43.03.15.27.39.05.17.29.41)

②图解特肖羊马龙鸡鼠

③合单+大数

更多资料尽在18590.com

- 澳门平特心水

- 香港平特心水

199期平兔→兔鼠(2连)→兔鼠猴(3连)

- 澳门传真

- 香港传真

澳门传真199期

解:【四四开】暗指生肖第4位兔(卯)、第44位轮回为鼠(子);【零五零六一三开】对应蛇(巳,第6)、马(午,第7)、龙(辰,第5);【零一二头】指鼠(0)、牛(1)、虎(2);【烟雾渺渺】喻龙腾云雨;【前人余荫】应狗(戌,忠守祖业)。生肖解:鼠(零数开头,四四轮回)兔(四数本位,柔中藏机)龙(零五云雨,国运象征)蛇(零六灵变,烟雾潜行)马(一三奔腾,买单双选)牛(一二稳进,厚德载福)狗(守荫护家,谨记前缘)——数理国运相合,七肖暗藏天时地利

七肖:鼠兔龙蛇马牛狗

五肖:鼠兔龙蛇马

三肖:鼠兔龙

主特:06.18.15.27.14.26.37.36.29.08

更多资料尽在18590.com

澳门传真198期

解:这段诗句暗藏数字玄机与生肖竞逐之象:四七开(4/7或11)、二一一五(2/11/5)等数字指向生肖排序;士气高跑在前强调竞争性,末句则隐喻超然独行的生肖特质。【生肖解码】兔(4位)跃青草占先机,马(7位)踏烽火破重围;牛(2位)扛旗稳中求,龙(5位)腾云震天威;狗(11位)戍关守擂胜,鼠(1位,21-15-5)窃时快如飞;猪(12位)卧泥笑红尘——七肖演尽竞逐戏,数字为钥破玄扉!(注:以4/7/2/11/5对应生肖排序,鼠猪体现子然一身,融合数字运算与竞速意象)

七肖:兔马牛龙狗鼠猪

五肖:兔马牛龙狗

三肖:兔马牛

主特:15.27.24.36.05.17.14.08.18.19

更多资料尽在18590.com

澳门传真197期

解:这段文字是生肖彩票或运势预测的隐喻诗,结合数字和生肖暗示机会与财运。以下是解读和7个生肖的对应表达(选鼠、虎、兔、马、羊、猴、狗为例)1710:鼠(一三开):首句一三开可能指鼠(排第一)与三合局(猴/龙),象征机遇潜伏需灵活把握38。虎(三十九):财运享通三十九中,39可拆解为3(虎的三合贵人运)和9(持久力),虎年需借势突破710。兔(零九一零):数字0901或关联兔的六合贵人(狗),提示谨慎选择合作方向29。马(中间发财):马为中间生肖,火土相生之日(如丙戌)易得偏财46。羊(二十八):渔翁得利对应未羊,28或指2月8日前后,需静待时机18。猴(五月六留意):猴属金,五月过半(农历六月)土生金,提示关注人际资源37。狗(双红合家欢):戌狗与双红(火土旺),二头买中或指合作共赢69。核心:数字暗藏生肖排序与五行生克,7生肖分别代表机遇(鼠)、魄力(虎)、贵人(兔)、偏财(马)、耐心(羊)、资源(猴)、合作(狗)

七肖:鼠虎兔马羊猴狗

五肖:鼠虎兔马羊

三肖:鼠虎兔

主特:06.18.16.28.15.27.36.35.34.08

更多资料尽在18590.com

澳门传真196期

解:这段文字结合了生肖运势、数字隐喻和天气提示:四四开,三六七九财运到:数字对应生肖排序(鼠1牛2…猪12),四为兔,三六为蛇/猴,七九为马/鸡,寓意这些生肖近期偏财旺15。高温降火:呼应夏季养生,强调补水防暑26。三七十一指猴(7)、狗(11),暗喻美猴王孙悟空的传奇7。零九一零为鼠(1)、鸡(10),中间生肖或指龙(5),预示机遇需谨慎把握49。生肖演绎:猴(申):灵活抓财运(三七主位)鸡(酉):偏财机遇(七九联动)龙(辰):贵人提携(中间发财)蛇(巳):智慧生财(三六暗藏)兔(卯):稳中求胜(四四平衡)鼠(子):暗藏先机(零九开端)狗(戌):忠诚护财(十一收官)(注:数字与生肖排序关联,高温提示参考夏日养生

七肖:猴鸡龙蛇兔鼠狗

五肖:猴鸡龙蛇兔

三肖:猴鸡龙

主特:34.46.09.21.14.26.37.15.18.08

更多资料尽在18590.com

澳门传真195期

解:这段谜语结合了数字、生肖和隐喻,核心是“二五开”“三五中”等数字游戏,暗示生肖的排列或特性。“二五开”:可能指数字2和5的组合,如2+5=7,对应马(生肖第7位)7。“浪沙淘金三五中”:三五即15,减去12(生肖周期)余3,对应虎(第3位)1。“灵码二号”:可能指兔(灵活敏捷)或龙(神话灵兽)6。“水中之物猜蛇龙”:直接点出蛇和龙(龙司水,蛇近水)4。“日防夜防家难防”:可能指鼠(家宅害虫)或狗(看家护院)8。“唯一冷码”:或指鸡(酉鸡,谐音“稀有”)5。综合相关生肖:虎、马、兔、龙、蛇、鼠、鸡,涵盖数字、习性及文化象征

七肖:虎马兔龙蛇鼠鸡

五肖:虎马兔龙蛇

三肖:虎马兔

主特:16.28.24.36.15.27.14.37.18.09

更多资料尽在18590.com

- 澳门五肖十码

- 香港五肖十码

199期推荐⑤肖:蛇猪狗鼠马

199期推荐③肖:蛇猪狗

199期推荐⑩码:13.25.19.31.08.20.18.30.24.36

199期推荐⑤码:13.25.19.31.08

更多资料尽在18590.com

197期推荐⑤肖:马鼠猴蛇鸡

197期推荐③肖:马鼠猴

197期推荐⑩码:24.36.06.18.34.46.13.25.09.21

197期推荐⑤码:24.36.06.18.34

更多资料尽在18590.com

196期推荐⑤肖:鼠龙猪虎兔

196期推荐③肖:鼠龙猪

196期推荐⑩码:06.18.14.26.19.31.16.28.15.27

196期推荐⑤码:06.18.14.26.19

更多资料尽在18590.com

195期推荐⑤肖:龙马鸡兔蛇

195期推荐③肖:龙马鸡

195期推荐⑩码:14.26.24.36.09.21.15.27.13.25

195期推荐⑤码:14.26.24.36.09

更多资料尽在18590.com

193期推荐⑤肖:马羊虎龙鼠

193期推荐③肖:马羊虎

193期推荐⑩码:12.24.23.35.16.28.14.26.06.18

193期推荐⑤码:12.24.23.35.16

更多资料尽在18590.com

192期推荐⑤肖:羊兔鸡鼠虎

192期推荐③肖:羊兔鸡

192期推荐⑩码:23.35.15.27.09.21.06.18.16.28

192期推荐⑤码:23.35.15.27.09

更多资料尽在18590.com

- 澳门红字肖

- 香港红字肖

199期红字暗码【有口皆碑】【07 18 37 48】

解析:指所有人的嘴都是活的记功碑。比喻人人称赞,犹如记载功业的石碑。解马兔龙猴虎蛇

解取特肖:马兔龙猴虎蛇

解取五肖:马兔龙猴虎

解取四肖:马兔龙猴

198期红字暗码【飞针走线】【09 16 27 32】

解析:意思是形容缝纫技术非常熟练。解虎蛇猪龙鼠兔

解取特肖:虎蛇猪龙鼠兔

解取五肖:虎蛇猪龙鼠

解取四肖:虎蛇猪龙

197期红字暗码【背信弃义】【11 26 30 47】

解析:意思是违背诺言,不讲道义,多指朋友间出卖友谊,多用于揭露、指责、谴责的场合。解猴鼠马猪狗羊

解取特肖:猴鼠马猪狗羊

解取五肖:猴鼠马猪

解取四肖:猴鼠马

195期红字暗码【双目如潭】【04 11 29 34】

解析:意思是一对眼睛像潭水一样明亮澄澈,楚楚动人。解马鼠龙鸡蛇狗

解取特肖:马鼠龙鸡蛇狗

解取五肖:马鼠龙鸡蛇

解取四肖:马鼠龙鸡

194期红字暗码【款款清歌】【07 22 35 48】

解析:常用来形容舒缓悠扬的歌唱或流水声,其核心含义体现在真挚情感与舒缓节奏的结合。解鼠虎牛蛇狗猪

解取特肖:鼠虎牛蛇狗猪

解取五肖:鼠虎牛蛇狗

解取四肖:鼠虎牛蛇

- 澳门平五不中

- 香港平五不中

199期【27.28.44.17.05】?

196期【03.28.40.24.07】准

195期【10.35.14.04.37】准

193期【39.41.13.48.31】准

192期【06.44.27.04.09】准

190期【15.47.13.45.01】准

189期【47.23.22.05.07】准

188期【04.08.34.11.29】准

- 澳门传真20码

- 香港传真20码

199期澳门内幕传真20码开?00

特码玄机:301 179(兔15)16+18= ?

夜晚来临满天星,春雨已过月如画

提供20码:

16 25 30 13 12 39 31 44 20 36

33 15 26 48 17 35 08 34 01 22

- 澳门精准单双

- 香港精准单双

199期精准单双〖双数〗开:?00准

- 澳门玄机诗

- 香港玄机诗

199期【澳彩玄机诗】

大报横石椅,视梦历劫难:开?00

解:

198期【澳彩玄机诗】

东方海映红,猛兽不胜数:开猪43

解:特码开猪43

197期【澳彩玄机诗】

阵阵乌云天,阴暗风四吹:开猴34

解:特码开猴34

196期【澳彩玄机诗】

莫惜一四衣,须惜四六时:开龙14

解:特码开龙14

195期【澳彩玄机诗】

行乐在谁边,红楼幸福家:开蛇25

解:特码开蛇25

- 澳门跑狗图

- 香港跑狗图

199期跑狗一字記之曰:【拉】

拉拉扯扯,纠纏不休。其實只須輕放手

苦惱自尋,徒惹煩憂。出岫雲心任漂浮

解:【拉拉扯扯】如蛇绞树枝般执念深重;【轻放手】需效兔脱笼的灵巧;【自寻烦恼】似牛抵角般固执;【云心漂浮】当如龙腾九天的洒脱;而最终解脱可学猪的憨淡自然。生肖解:蛇(纠缠不放的执念化身)兔(轻盈放手的智慧代表)牛(钻牛角尖的固执典型)龙(超然物外的云心象征)猪(憨厚放下的生活智者)——五肖演绎人生执念与放下的艺术:蛇之缠、兔之灵、牛之固、龙之逸、猪之淡,恰是执与放的生命五重境。精要: 蛇兔示执放两极,牛显执念苦果,龙展解脱境界,猪归生活本真

五肖:蛇兔牛龙猪

四肖:蛇兔牛龙

三肖:蛇兔牛

二肖:蛇兔

一肖:蛇

197期跑狗一字記之曰:【抛】

智者從容,略施小計。双码四四被唤得

抛石引金,富貴流芳。侍意捣乱好开心

解:这段玄机诗句暗藏智慧与机遇,用生肖诠释如下:猴(智者從容):象征机灵善变,以智取胜,蛇(略施小計):代表谋略过人,暗中布局,龙(双码四四):4+4=8对应八卦,龙主富贵,马(抛石引金):寓意行动力强,把握转机,猪(好开心):象征福气自来,圆满收场。核心解析:诗句展现智慧致富之道:猴蛇主谋略(从容施计)→龙马主机遇(数字玄机与行动)→猪主福报。其中双码四四既暗藏数字8的财富密码,又呼应八卦方位;抛石引金喻示以小博大的智慧。五生肖精准对应谋划-行动-收获的全过程,省略其他生肖以突出重点

五肖:猴蛇龙马猪

四肖:猴蛇龙马

三肖:猴蛇龙

二肖:猴蛇

一肖:猴

195期跑狗一字記之曰:【味】

憶苦思甜,纯屬妄想。説是人生夢一場

嗚呼哀哉,伏為尚饗,五味紛陳已盡嚐

解:这段充满禅意的人生感悟,用生肖便能完美诠释:鼠(钻营半生)——象征憶苦思甜的徒劳,终日奔波却难逃命运,兔(月宫捣药)——对应人生夢一場的虚幻,如月宫般遥不可及,蛇(蜕皮重生)——暗喻纯屬妄想的醒悟,褪去执念方见真我,马(驰骋千里)——体现五味紛陳的历程,尝尽人间百味,猪(憨厚大智)——诠释嗚呼哀哉后的超脱,难得糊涂才是真。这组生肖串联起一个完整的人生觉悟过程:从鼠的汲汲营营,到兔的梦幻泡影,经蛇的蜕变换骨,历马的百味人生,终达猪的大智境界。五生肖暗合贪嗔痴慢疑五毒,又指向放下的智慧

五肖:鼠兔蛇马猪

四肖:鼠兔蛇马

三肖:鼠兔蛇

二肖:鼠兔

一肖:鼠

194期跑狗一字記之曰:【等】

獨自閑躺,似有所等。三九三四必开一

雲淡風輕,時光流轉。四九开大绿波起

解:此签暗藏静候机缘的天道密码:独卧待运至(似有所等),三九/三四藏关键抉择,四九绿波喻大势终起(绿为东方木,主生机勃发)。用生肖点破天机:牛(丑时反刍,耐守三九寒)兔(卯木裂冰,巧开三四局)蛇(巳火隐忍,暗合四九数)马(午驰绿野,乘风破浪时)猪(亥水载福,苦尽甘来日)五行剧幕:牛土奠基→兔木破茧→蛇火炼志→马火燎原→猪水润终(五肖暗合蛰伏-破局-腾飞三重天道,余肖暂隐)

五肖:牛兔蛇马猪

四肖:牛兔蛇马

三肖:牛兔蛇

二肖:牛兔

一肖:牛

193期跑狗一字記之曰:【友】

有朋自來,不亦樂乎,好友一生互關顧

親切關懷,溫馨招呼,同行共歷甘與苦

解:这段文字歌颂真挚友情,以生肖特性诠释朋友间的互助与温情——有朋自来:如狗(忠诚守候),始终如一;马(热情主动),广结善缘。互相关顾:似牛(踏实可靠)默默付出,羊(温和体贴)细腻关怀。共历甘苦:如龙(仗义担当),危难中挺身相助。生肖友情特质:狗(不离不弃)马(真诚热情)牛(坚实后盾)羊(暖心陪伴)龙(患难与共)寓意:挚友当如狗之忠、马之诚、牛之稳,兼有羊的柔与龙的勇,方能同行一生

五肖:狗马牛羊龙

四肖:狗马牛羊

三肖:狗马牛

二肖:狗马

一肖:狗

- 澳门绝杀三只

- 香港绝杀三只

199期绝杀三只【龙牛蛇】开?00准

197期绝杀三只【鸡猪虎】开猴34准

196期绝杀三只【马鸡羊】开龙14准

193期绝杀三只【龙猪狗】开马24准

190期绝杀三只【猴猪羊】开鼠18准

188期绝杀三只【鼠马蛇】开兔15准

186期绝杀三只【羊兔龙】开狗08准

185期绝杀三只【羊猴虎】开牛05准

184期绝杀三只【狗兔龙】开虎28准

183期绝杀三只【猴狗虎】开鸡33准

182期绝杀三只【猪兔虎】开鼠42准

181期绝杀三只【蛇马猴】开羊23准

180期绝杀三只【虎鸡龙】开牛29准

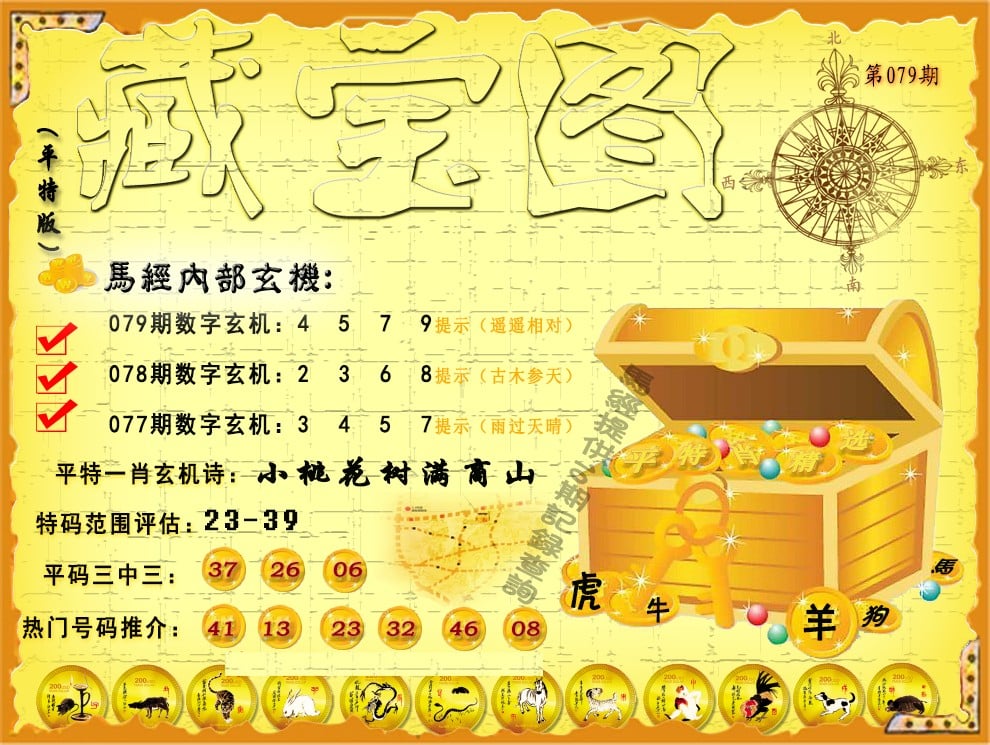

- 澳门藏宝图

- 香港藏宝图

199期平特藏宝图玄机

【今期猪鼠无希望】

解:今期猪鼠无希望,平特龙羊

特码范围评估:01-19

推荐平码:10.18.19.17.29.07

开奖结果:00-00-00-00-00-00T00

197期平特藏宝图玄机

【特出双数六合中】

解:特出双数六合中,平特马龙

特码范围评估:01-19

推荐平码:20.18.29.07.19.08

开奖结果:15-25-10-43-12-24T34

194期平特藏宝图玄机

【今期生肖六六来】

解:今期生肖六六来,平特蛇鼠

特码范围评估:01-28

推荐平码:10.18.19.07.29.02

开奖结果:11-30-46-43-03-07T29

193期平特藏宝图玄机

【家中有宝一定发】

解:家中有宝一定发,平特龙虎

特码范围评估:01-19

推荐平码:20.19.29.18.09.03

开奖结果:17-16-04-14-06-42T24

- 澳门四不像

- 澳门传真图

- 澳门跑马图

- 新挂牌彩图

- 另版跑狗图

- 老版跑狗图

- 澳门玄机图

- 玄机妙语图

- 六麒麟透码

- 平特一肖图

- 一字解特码

- 新特码诗句

- 四不像玄机

- 小黄人幽默

- 新生活幽默

- 30码中特图

- 澳门抓码王

- 澳门天线宝

- 澳门一样发

- 曾道人暗语

- 鱼跃龙门报

- 无敌猪哥报

- 特码快递报

- 一句真言图

- 新图库禁肖

- 三怪禁肖图

- 正版通天报

- 三八婆密报

- 博彩平特报

- 七肖中特报

- 神童透码报

- 内幕特肖B

- 内幕特肖A

- 内部传真报

- 澳门牛头报

- 千手观音图

- 梦儿数码报

- 六合家宝B

- 合家中宝A

- 六合简报图

- 六合英雄报

- 澳话中有意

- 彩霸王六肖

- 马会火烧图

- 狼女侠客图

- 凤姐30码图

- 劲爆龙虎榜

- 管家婆密传

- 澳门大陆仔

- 传真八点料

- 波肖尾门报

- 红姐内幕图

- 白小姐会员

- 白小姐密报

- 澳门大陆报

- 波肖一波中

- 庄家吃码图

- 发财波局报

- 36码中特图

- 澳门男人味

- 澳门蛇蛋图

- 白小姐救世

- 周公玄机报

- 值日生肖图

- 凤凰卜封图

- 腾算策略报

- 看图抓码图

- 神奇八卦图

- 新趣味幽默

- 澳门老人报

- 澳门女财神

- 澳门青龙报

- 财神玄机报

- 内幕传真图

- 每日闲情图

- 澳门女人味

- 澳门签牌图

- 澳六合头条

- 澳门码头诗

- 澳门两肖特

- 澳门猛虎报

- 金钱豹功夫

- 看图解特码

- 今日闲情1

- 开心果先锋

- 今日闲情2

- 济公有真言

- 四组三连肖

- 金多宝传真

- 皇道吉日图

- 澳幽默猜测

- 澳门红虎图

- 澳门七星图

- 功夫早茶图

- 鬼谷子爆肖

- 观音彩码报

- 澳门不夜城

- 挂牌平特报

- 新管家婆图

- 凤凰天机图

- 赌王心水图

- 佛祖禁肖图

- 财神报料图

- 二尾四码图

- 东成西就图

- 12码中特图

- 单双中特图

- 八仙指路图

- 八仙过海图

- 正版射牌图

- 澳门孩童报

- 通天报解码

- 澳门熊出没

- 铁板神算图

- 杀料专区

- 独家资料

- 独家九肖

- 高手九肖

- 澳门六肖

- 澳门三肖

- 云楚官人

- 富奇秦准

- 竹影梅花

- 西门庆料

- 皇帝猛料

- 旺角传真

- 福星金牌

- 官方独家

- 贵宾准料

- 旺角好料

- 发财精料

- 创富好料

- 水果高手

- 澳门中彩

- 澳门来料

- 王中王料

- 六合财神

- 六合皇料

- 葡京赌侠

- 大刀皇料

- 四柱预测

- 东方心经

- 特码玄机

- 小龙人料

- 水果奶奶

- 澳门高手

- 心水资料

- 宝宝高手

- 18点来料

- 澳门好彩

- 刘伯温料

- 官方供料

- 天下精英

- 金明世家

- 澳门官方

- 彩券公司

- 凤凰马经

- 各坛精料

- 特区天顺

- 博发世家

- 高手杀料

- 蓝月亮料

- 十虎权威

- 彩坛至尊

- 传真內幕

- 任我发料

- 澳门赌圣

- 镇坛之宝

- 精料赌圣

- 彩票心水

- 曾氏集团

- 白姐信息

- 曾女士料

- 满堂红网

- 彩票赢家

- 澳门原创

- 黃大仙料

- 原创猛料

- 各坛高手

- 高手猛料

- 外站精料

- 平肖平码

- 澳门彩票

- 马会绝杀

- 金多宝网

- 鬼谷子网

- 管家婆网

- 曾道原创

- 白姐最准

- 赛马会料